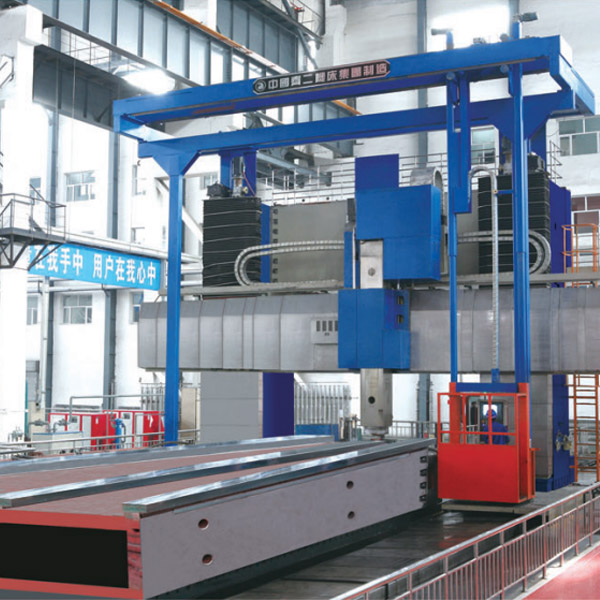

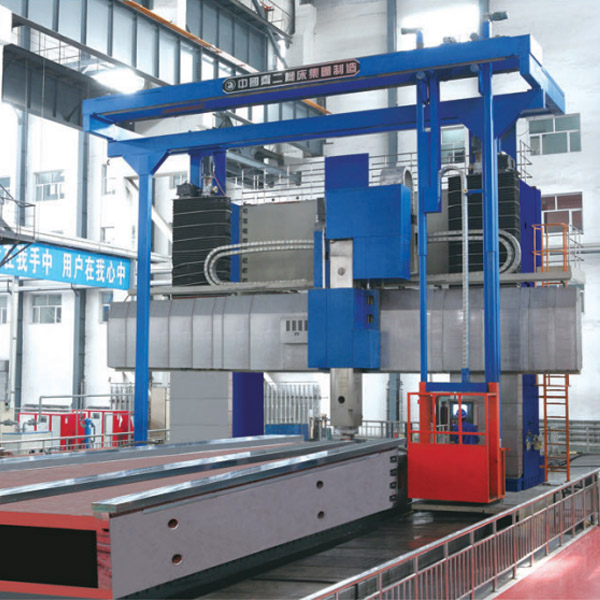

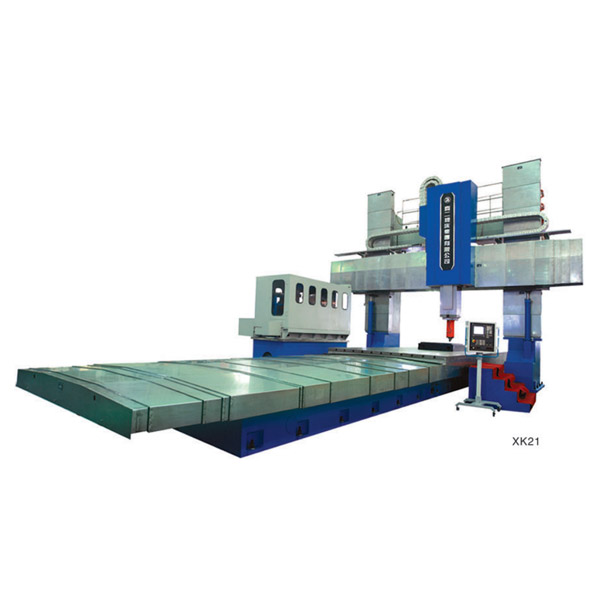

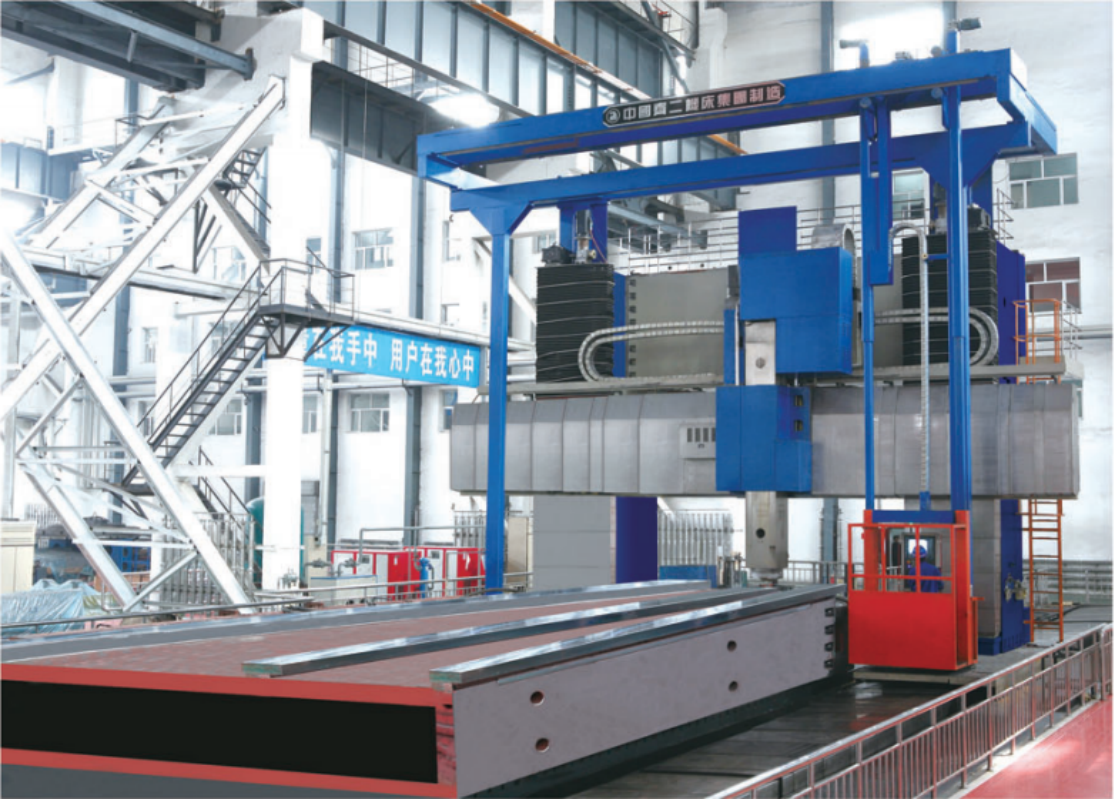

CNC Traveling Bridge Type Boring And Milling Machine SERIES GM28/27

Brand QIER WAJI CNC MACHINE

Product origin CHINA LIAONING

Delivery time 3 months

Supply capacity 2-5 units per month

1. Fixed table milling features four feed axes (any three-axis linkage), making it easy to machine complex workpieces.

2. Fixed table milling utilizes a hydrostatic worm and nut structure and a high-precision ball screw drive, dual servo synchronization, and fully closed-loop control.

3. Fixed table milling can be equipped with an optional optical scale for fully closed-loop position feedback, further improving positioning accuracy and repeatability.

Professional technical engineers will guide customers in selecting the type and model of fixed table milling system based on their production needs and individual requirements.

The contract is signed with a professional technical agreement, and the fixed table milling system delivered will fully comply with the agreed specifications.

Our sales and after-sales staff will respond to any questions customers may have regarding fixed table milling within six hours of receiving the inquiry.

If necessary, we will dispatch professional after-sales technicians to provide on-site guidance on the installation and commissioning of the fixed table milling system. (All technicians have at least five to ten years of experience in the industry.)

Introduction of CNC milling machine:

This CNC milling machine combines modern CNC technology with precision machining processes. Fixed table milling bed base is constructed of high-strength cast iron, ensuring its rigidity and vibration resistance. The gantry frame is constructed of welded steel plates, while the worktable, slide, and ram are molded using resin sand, further enhancing the machine's precision and stability. Equipped with high-precision spindle bearings and a hydraulic cylinder balancing system, this machine ensures smooth movement of the ram and milling head, improving machining accuracy.

This CNC milling machine is suitable for rough and fine machining of complex shapes on large machine bases, large housings, and various rotary parts. Large gantry milling machines is also particularly well-suited for machining large precision parts in industries such as shipbuilding, power generation, energy, transportation, mining, metallurgy, and engineering machinery.

Features of Traveling bridge boring machine:

▲ The traveling bridge boring machine is available in two types: gantry and table. Each type can be further divided into fixed-beam and adjustable-beam models, depending on user requirements.

▲ Users can choose between linear guides (GM series) or hydrostatic guides (XK series) for the traveling bridge boring machine based on their processing needs.

▲ The main drive features a two-speed continuously variable transmission, achieving high torque at low speeds and constant power at high speeds. The traveling bridge boring machine can meet the diverse process requirements of both roughing and finishing.

▲ When equipped with appropriate accessories, the traveling bridge boring machine can perform various machining operations, including milling, boring, drilling (drilling, reaming, and tapping), on multiple workpiece surfaces (excluding mounting surfaces) in a single clamping. This eliminates errors caused by multiple clamping, positioning, zeroing, alignment, and tool setting operations, improving machining accuracy and efficiency.

▲ A variety of accessories with different functions can be added to meet user requirements.

▲ The accessories feature automatic indexing and automatic exchange functions. The large gantry milling machines can also be equipped with an optional tool magazine for automatic tool changing.

Specifications of CNC milling machine:

Specification/Model | Unit | GM2835/GM2735 | GM2840/GM2740 | GM2846/GM2746 | GM2850/GM2750 | GM2860/GM2760 |

Table Surface Size of CNC Milling Machine (W×L) | mm | 2500X8000 | 3000X10000 | 3600X12000 | 4000X15000 | 5000X20000 |

Gantry Frame Width | mm | 3600 | 4000 | 4600 | 5000 | 6000 |

Table Load of CNC Milling Machine | Vm2 | 8 | 10 | 10 | 10 | 10 |

Axis X Travel of CNC Milling Machine | mm | 8500 | 10500 | 12500 | 16000 | 20500 |

Axis Y Travel of CNC Milling Machine | mm | 4600 | 5000 | 5600 | 6000 | 7000 |

Axis Z Travel of Fixed Table Milling | mm | 1250 | 1250 | 1500 | 1500 | 1500 |

Axis W Travel (Only For Series GM28) | mm | 1500 | 1500 | 2000 | 2500 | 2500 |

Feed Rate Of Each Axis | mm/min | X/Y:10000 Z:4000 W:2000 | X/Y:10000 Z:4000 W:2000 | X/Y:10000 Z:4000 W:2000 | X/Y:10000 Z:4000 W:2000 | X/Y:16000 Z:4000 W:2000 |

Ram Section of Fixed Table Milling | mm | 500X500 | 500X500 | 500X500 | 500X500 | 500X500 |

Axis C Indexing of Fixed Table Milling | 4齿90° | 4齿90° | 4齿90° | 4齿90° | 4齿90° | |

Main Motor Power of Fixed Table Milling | kw | 37 | 37 | 37 | 60 | 60 |

Speed Range of Traveling Bridge Boring Machine | rpm | 2-2000 | 2-2000 | 2-2000 | 2-2000 | 2-2000 |

Our large gantry milling machines offer advantages over conventional CNC milling machine:

1.Our large gantry milling machines utilize CAD-optimized, modular designs, allowing for flexible configuration of accessories such as milling heads, tool magazine capacity, and cooling systems based on user needs, providing a truly customized solution.

2.Conventional large gantry milling machines have limited load capacity, which can easily lead to deformation and reduced precision when machining large workpieces. Our large gantry milling machines feature a high-load-bearing table, a sturdy bed and column structure, and a ball screw drive, ensuring smooth crosshead movement and long-term stable machining accuracy.

3.Conventional CNC milling machine are prone to low efficiency and insufficient torque during slow, heavy-duty machining. Our large gantry milling machines, equipped with a high-speed spindle unit and precision planetary gearbox transmission, not only offer high torque and efficiency, but also maintain stability and efficiency even in slow, heavy-duty machining conditions, resulting in machining performance far exceeding that of conventional machine tools.

Logistics and transportation of double column milling machine:

We ship our double column milling machine by sea, ensuring secure packaging and a fast and safe arrival. The typical delivery time for a double column milling machine is approximately 1.5 to 6 months. Payment: A 30% deposit is required, with the remaining 70% payable prior to shipment.

Tips:

Work clothes and safety goggles must be worn. Do not wear gloves when operating large gantry milling machines.

Before starting a double column milling machine, ensure that the tool and workpiece are securely clamped. Do not adjust or measure the workpiece while the machine is running.

Do not clean chips or touch rotating parts while the double column milling machine is running.

Regularly check the installation of the limit blocks to prevent the double column milling machine's worktable from exceeding its range.

Company profile:

QiEr specializes in the research, development, and manufacturing of large-scale CNC equipment, including CNC milling machines. We are actively expanding into the market and have developed over ten different types of traveling bridge boring machines. Our vertical CNC milling machines, in particular, have replaced similar imported products in China.

We honor our commitment to quality assurance for our double column milling machines. We sincerely hope to provide you with the highest quality double column milling machines and superior service at the most competitive prices.