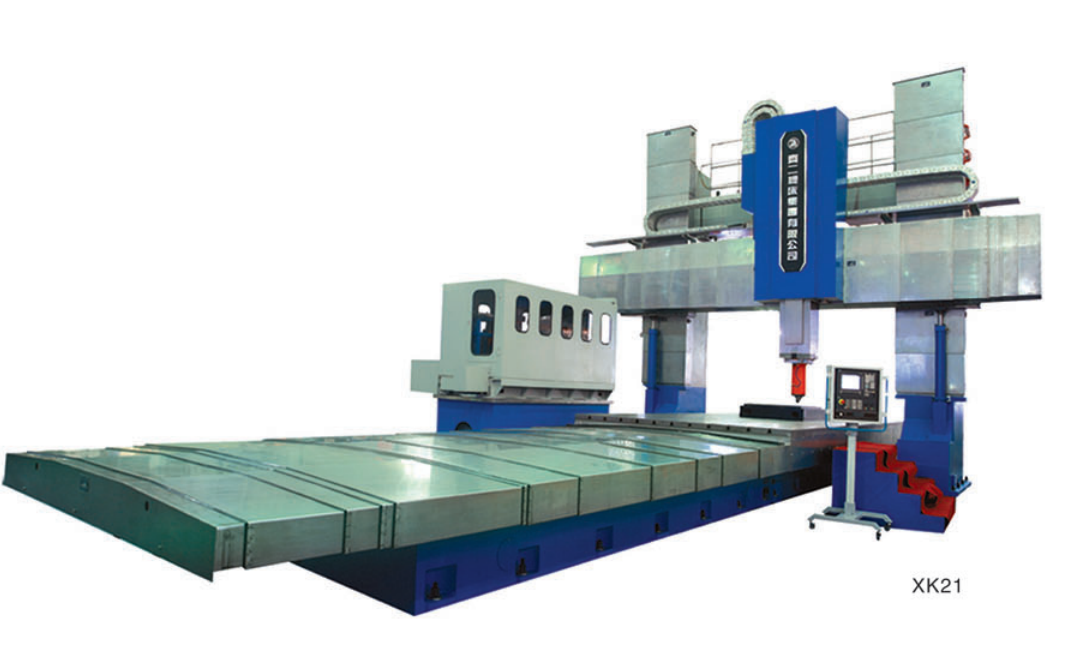

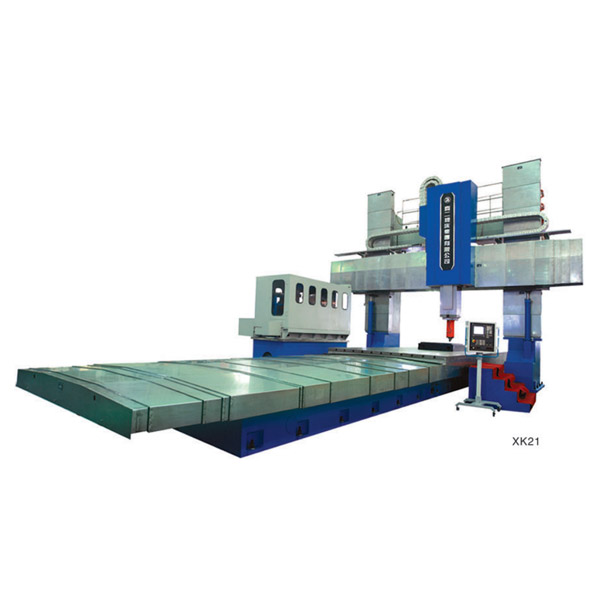

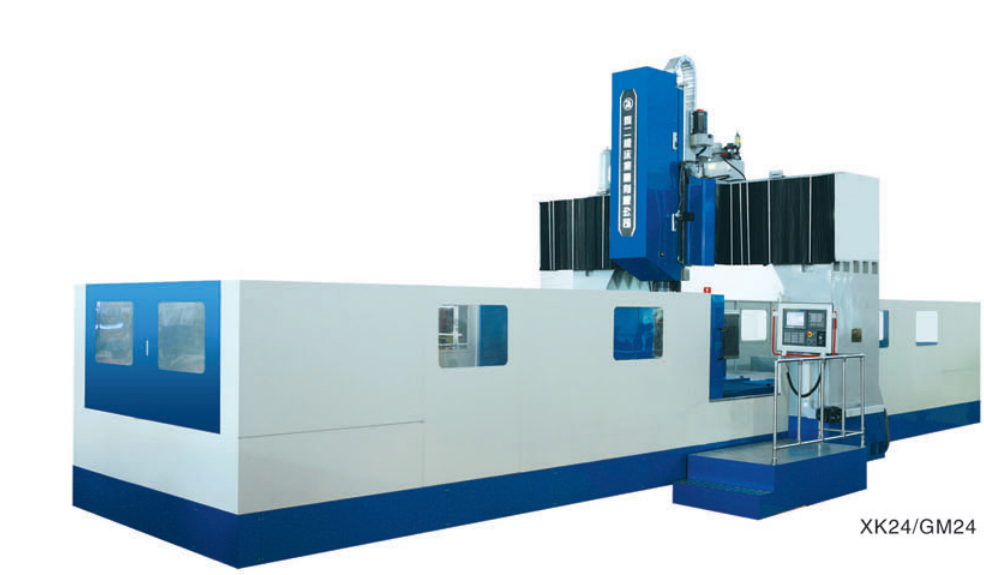

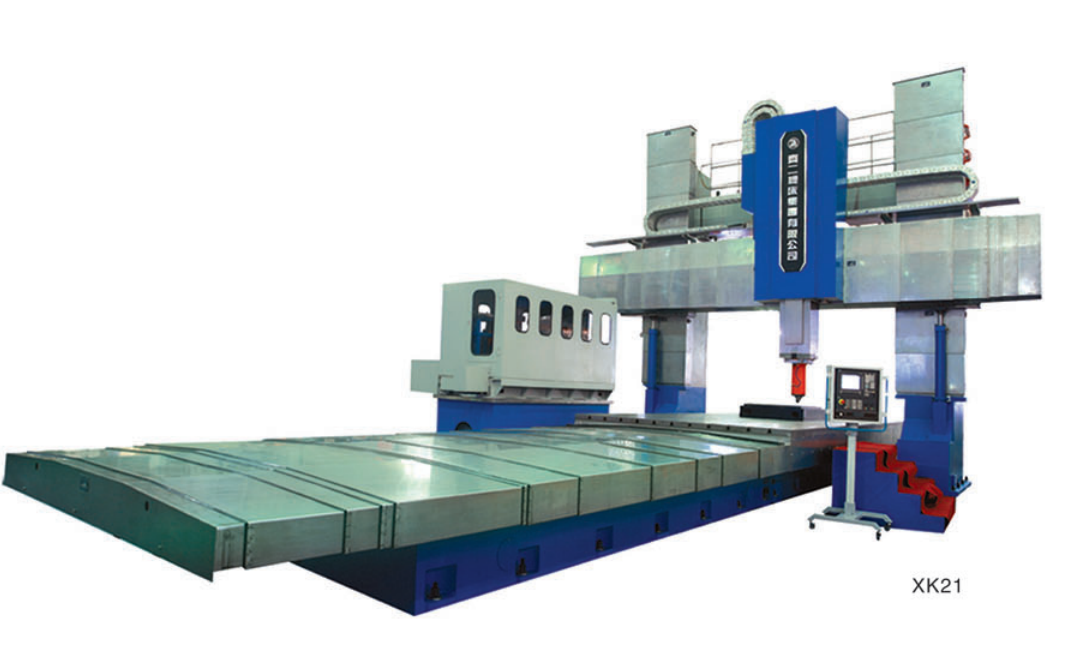

CNC Fixed Bridge Type Boring And Milling Machine SERIES GM21/24

Brand QIER WAJI CNC MACHINE

Product origin CHINA LIAONING

Delivery time 3 months

Supply capacity 2-5 units per month

1. Key components of the CNC portal machine are made of high-strength alloys and have undergone hardness testing and other processes.

2. After assembly, the CNC portal machine undergoes full-load, long-term operation testing to verify its stability and reliability under actual operating conditions.

3. Professional engineers with over 10 years of industry experience are responsible for the inspection and commissioning of the CNC portal machine, ensuring compliance with international standards.

QiEr provides customers with remote video and telephone guidance to resolve urgent issues encountered during operation or commissioning, reducing CNC portal machine downtime.

QiEr offers regular maintenance plans and remote reminders for CNC portal machines, helping customers proactively perform maintenance, extending equipment lifespan and preventing production downtime caused by unexpected failures.

Introduction of CNC portal machine:

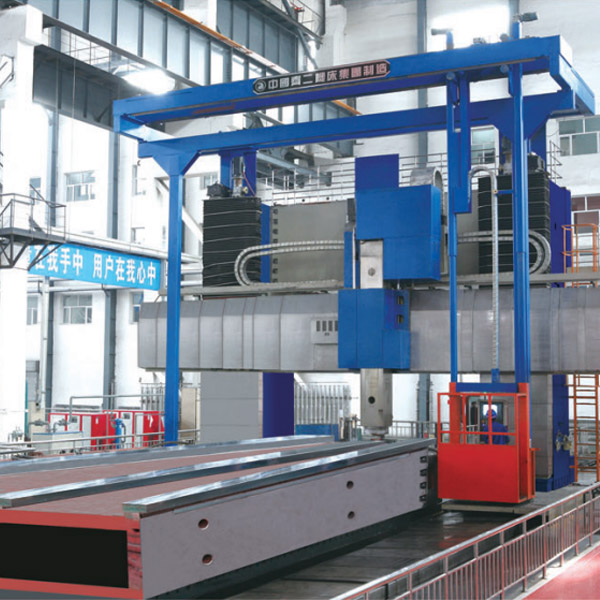

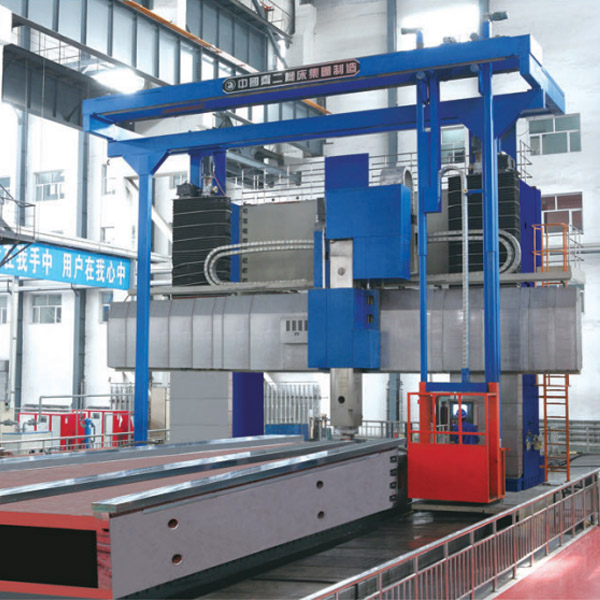

CNC portal machine is the leading product independently developed, designed, produced and manufactured by Qi Er. The GM series CNC portal machine is a fixed-beam gantry machining center in which the worktable moves back and forth on the bed (X-axis), the crossbeam and gantry frame of the CNC portal machine are fixed, the cross slide of the CNC portal machine moves left and right on the crossbeam (Y-axis), and the ram of the CNC portal machine moves up and down (Z-axis). The CNC portal machine is suitable for rough and fine machining of complex shapes of large machine base parts, large box parts and various rotating parts. It is particularly suitable for machining large precision parts in industries such as shipbuilding, power generation, energy, transportation, mining, metallurgy, and engineering machinery. The CNC portal machine achieves high-speed and efficient machining. After the workpiece is clamped once, the large horizontal boring mill can continuously complete multiple processes such as milling, boring, drilling, reaming, and rigid tapping with high precision and high efficiency.

Features of CNC boring machine:

▲CNC boring machines are available in two types: gantry and tabletop. Each type can be further configured as a fixed beam or adjustable beam, depending on user requirements.

▲Users can choose between linear guides (GM series) or hydrostatic guides (XK series) for the CNC boring machine based on their processing needs.

▲The main drive features a two-speed continuously variable transmission, achieving high torque at low speeds and constant power at high speeds. The CNC boring machine can meet the diverse process requirements of both roughing and finishing.

▲Equipped with appropriate accessories, the CNC boring machine can perform various machining operations, including milling, boring, drilling (drilling, reaming, and tapping), on multiple workpiece surfaces (excluding mounting surfaces) in a single clamping. This eliminates errors caused by multiple clamping, positioning, zeroing, alignment, and tool setting operations, improving machining accuracy and efficiency.

▲A variety of accessories with different functions can be added to meet user requirements.

▲The accessories feature automatic indexing and automatic exchange functions. The CNC boring machine also offers an optional tool magazine for automatic tool changing.

Specifications of CNC boring machine:

Specification/Model Table Surface Size (W×L) | Unit | GM2125/GM2425 | GM2130/GM2430 | GM2135/GM2435 | GM2140/GM2440 | GM2150/GM2450 |

Gantry Frame Width (With Cover) | mm | 3100 | 3600 | 4100 | 4600 | 5600 |

Machine Load of CNC Boring Machine | Vm2 | 5 | 8 | 8 | 10 | 10 |

Axis X Travel of CNC Boring Machine | mm | 6200 | 9000 | 10500 | 12500 | 16500 |

Axis Y Travel of CNC Boring Machine | mm | 4250 | 4750 | 5100 | 5600 | 6600 |

Axis Z Travel of Traveling Table Milling | mm | 900 | 900 | 1500 | 1500 | 1500 |

Axis W Travel (Only For Series GM21) | mm | 1500 | 2000 | 2000 | 2500 | 2500 |

Feed Rate of Each Axis | mm/min | X/Y:10000 Z :4000 W :2000 | X/Y:10000 Z :4000 W :2000 | X/Y:10000 Z :4000 W :2000 | X/Y:10000 Z :4000 W :2000 | X/Y:10000 Z :4000 W :2000 |

Ram Section of Traveling table Milling | mm | 380X380 | 380X380 | 500X500 | 500X500 | 500X500 |

Axis C Indexing of Traveling table Milling | 72齿5° | 72齿5° | 4齿90° | 4齿90° | 4齿90° | |

Main Motor Power of Traveling table Milling | KW | 30 | 30 | 37 | 60 | 60 |

Speed Range of Main Spindle | r/min | 2-2000 | 2-2000 | 2-2000 | 2-2000 | 2-2000 |

Benefits of using traveling table milling:

Improved processing efficiency:

The traveling table milling, with its high-rigidity design, enables customers to achieve higher processing efficiency and shorten lead times for small and medium-volume production.

Guaranteed processing accuracy and stability:

The static and dynamic performance of the traveling table milling is taken into account during production design, ensuring high precision and stability during long-term processing and reducing scrap rates.

Enhanced processing flexibility:

A single machine can be used for multiple purposes. The traveling table milling can accommodate parts of varying shapes and batch sizes, enhancing companies' ability to handle diverse orders.

Easy operation:

With its simple operation and easy adjustments, the traveling table milling reduces the need for highly skilled operators and reduces training and labor costs.

Key issues to consider when purchasing a CNC boring machine:

1. Does the X/Y/Z/W axis travel of the large horizontal boring mill meet the workpiece size?

2. Can the large horizontal boring mill complete multiple operations (milling, boring, drilling, tapping, and five-sided machining) in a single setup?

3. Does the large horizontal boring mill support different CNC systems (such as Siemens, FANUC, and Mitsubishi)?

Our large horizontal boring mills can meet all of these customer needs.

Certification of large horizontal boring mill:

We are certified to the GB/T 19001-2016 / ISO 9001:2015 quality management system. Our production process is controlled, ensuring stable and reliable quality for our Traveling table milling, meeting international standards.

Service uarantee of CNC boring machine:

Upon arrival, we provide smooth on-site installation of your large horizontal boring mill. If necessary, we will dispatch professional after-sales technicians with 5–10 years of industry experience to provide on-site installation and commissioning guidance.

We also provide replacement parts to minimize downtime and costs associated with large horizontal boring mill.

We conduct regular after-sales visits to collect customer feedback and enhance your service experience.

Company Profile:

Our company has established long-term partnerships with many renowned companies. We are 100% confident and dedicated, and every piece of equipment we produce undergoes rigorous testing. Our products offer superior quality, higher precision, smoother operation, more durable hardware, and exceptional service.

If you are interested in any of our Brad vertical lathes (double-column vertical lathes), please feel free to contact us.