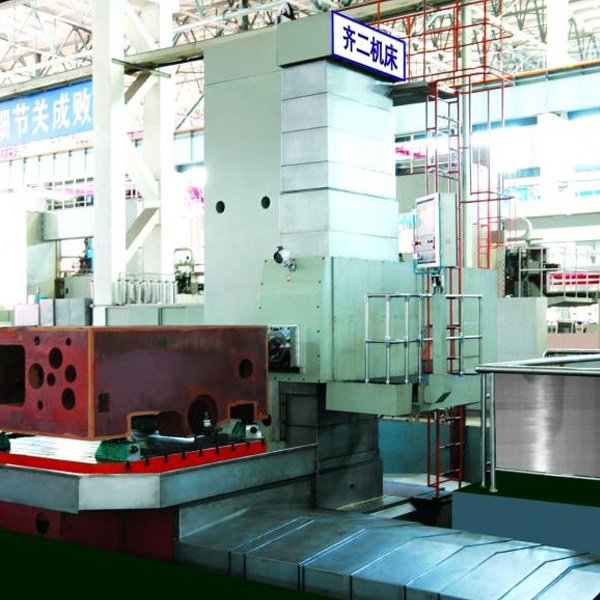

TK65/68 Series CNC Planer Type Milling And Boring Machine

Brand QIER WAJI CNC MACHINE

Product origin CHINA LIAONING

Delivery time 3 months

Supply capacity 2-5 units per month

1. Small milling machine has good rigidity, balance and heat dissipation performance, which provides a reliable guarantee for the high-speed operation of the headstock

2. Small milling machine has enhanced power and smooth operation

No need to worry about the mismatch between small milling machine and production! Our small milling machine can provide full-dimensional customized services according to your actual production scenarios.

If your plant space is limited, we can optimize the structural design of the small milling machine, while retaining the core processing performance of the small milling machine, compress the footprint of the small milling machine and adapt it to a compact workshop layout. If you need to process workpieces in special industries, the technical team will adjust the spindle speed range of the small milling machine, the milling head function module of the small milling machine, and even customize the special fixture and tool path scheme of the small milling machine to make the processing flow of the small milling machine and your process requirements seamless. Even if you have plans to upgrade your production capacity in the future, we can reserve the function expansion interface in the early design to avoid the additional cost of the later small milling machine transformation.

From the communication of small milling machine's needs to the implementation of the plan, engineers will follow up one-on-one throughout the process, so that every customization of small milling machine can accurately solve your production pain points. Want to know how your workshop adapts to your own small milling machine? Contact us immediately to provide your production scale, processing workpiece type and core requirements, and we will issue you a preliminary customized plan for small milling machine for free!

Introduction of milling machine:

This series of machines are applicable to machine large or middle size housing components, frames and moulds. After the completion of one-time workpiece setup, the machine can automatically complete multiple operations, such as milling, boring, drilling, reaming, countering, tapping, etc. The machine is capable of seven axes control and simultaneous control on any four of them, it is also capable of circular interpolation and 3-D contoured surface machining. With the installation of accessories, such as milling heads and facing plates, the machine operation capability can be increased.

The Structure features of Series TK65 (without ram) Linear Guideways for Axes X and W and rectangular guideways along Axes Y and Z forced lubrication guideways for Axis B.

The Structure features of Series TK68 (with ram) - Linear Guideways lor Axis X, Hydrostatic Guideways for Axes Y, V and W. forced lubrication guideways for Axis B, guiding bar for Axis Z.

Other models of the small milling machine series:

Small milling machine TK6513B,

Small milling machine TK6513B,

Small milling machine TK6516B,

Small milling machine TH6516B,

Small milling machine TK6813,

Small milling machine TH6813,

Small milling machine TK6816.

Structural characteristics of milling machine:

1. T-shaped bed layout The worktable always moves on the horizontal bed, with sufficient rigidity and good precision retention; the spindle can be CNC fed 550mm, and the axial resistance is large, which can be used for strong cutting; PTFE guide rail plate, there are rolling elements on the side for guidance, the friction between the guide rails is small, and the positioning accuracy is high.

2. X, Z coordinate guide rails are equipped with stainless steel pull-plate type protective cover, Y direction has accordion type protective cover, dustproof and waterproof protection guide rails.

3. The rotary circular guide rail of the worktable adopts cast iron-PTFE guide rail plate, and the imported thrust bearing is installed inside for unloading, stable movement, high positioning accuracy, and the bearing capacity can reach 5000kg.

4. Main shaft bearings and screw bearings are imported originals.

5. Each guide rail motion pair has an adjustable timing lubricating device to supply oil, which can ensure sufficient lubricating oil for each lubricating point.

6. Equipped with cooling device, water tray and screw-type chip conveyor; easy to remove chips.

7. Equipped with Siemens SINUMERIK 840D CNC system, AC spindle motor, AC feed servo motor and servo drive unit are imported original, advanced performance, safe and reliable.

Specifications of milling machine:

Specification/Model | Unit | TK6513B/TH6513B | TK6813/TH6813 | TK6516B/TH6516B | TK6816/TH6816J |

Boring Spindle Diameter | mm | φ130 | φ130 | φ160 | φ160 |

Mining Spindle End Diameter | mm | φ221.44 | φ221.44 | φ280 | φ280 |

Trable Travel | mm | 2500 | 2500 | 2500 | 2500 |

Boring Spindle Travel | mm | 800 | 800 | 900 | 1000 |

Ram Travel | mm | none; NA | 800 | none; NA | 1000 |

Headstock Travel | mm | 2000 | 2000 | 3000 | 3000 |

Column Travel | mm | 1000 | 1500 | 2000 | 2000 |

Boring Spindle Taper | ISO 50 | ISO 50 | ISO 50 | ISO 50 | |

Spindle Speed | r/min | 2-2000 | 2-2000 | 2-1500 | 2-1500 |

Feed Rate of Table. Headstock am Column | m/min | 5-6000 | 5-8000 | 5-8000 | 5-6000 |

Reverse cost optimization of large machining center:

Our large machining center can reverse optimize the configuration and process plan of the large machining center according to your expected single-piece processing cost. For example, a lightweight large machining center solution was customized for a foundry in Spain. Under the premise of meeting the accuracy requirements, the procurement cost of large machining center was reduced by 25% and the energy consumption cost was reduced by 18%. By choosing our large machining center, you don't have to compromise on production quality and make cost control more flexible.If you are interested, you can contact us to get an exclusive large machining center cost reduction plan!

Certification blessing of large machining center:

Our large machining center has passed a number of authoritative certifications in Europe and the United States such as CE, UL, etc., and is produced in strict accordance with ISO international standards and EN European standards. These certifications are not only an endorsement of the quality of large machining center, but also save you the cumbersome access review process, allowing large machining center to be put into production quickly and reduce compliance risks. Contact us for complete large machining center certification documents and compliance details!

The acceptance list of large machining center is provided:

We provide a detailed acceptance list of the arrival of the large machining center, which clearly lists the main body of the large machining center, the quantity and specifications of the accessories and tools of the large machining center, and marks the inspection points of the key components of the large machining center, and includes a description of the acceptance process of the large machining center. Customers can check the large machining center item by item according to the list to avoid missed inspections or wrong receipts, and problems found in the acceptance can be quickly clarified and responsibilities can be resolved through efficient communication. Contact us to obtain a template for the acceptance list of large machining center!

Assistance with customs declaration information of large machining center:

We can provide customers with the certificate of origin, product manual, compliance certificate and other information required for large machining center's customs declaration, and assist in checking the integrity of the information to prevent delays in large machining center's customs declaration due to missing or inconsistent information, and improve the efficiency of customs clearance. Contact us to consult the customs declaration assistance process of large machining center!

About our loading:

We choose to ship by sea, and the packaging is firm to ensure that your goods arrive safely and quickly. The delivery time is generally about 1.5~6 months. Regarding the payment method, you need to pay 30% in advance, and 70% of the balance can be paid before delivery.